In this article, you will discover a step-by-step guide on how to effectively use a power doweling jig to create strong and sturdy dowel joints. Whether you are a woodworking enthusiast or a DIY beginner, this comprehensive tutorial will provide you with all the necessary information and techniques to confidently tackle your next project. From selecting the right materials to mastering the drilling process, you will soon be able to effortlessly create precise and professional dowel joints with the help of a power doweling jig. So grab your tools and get ready to enhance your woodworking skills!

Choosing the Right Jig

When it comes to using a power doweling jig for creating dowel joints, the first step is to choose the right jig for your specific needs. There are different types of jigs available on the market, each with their own advantages and limitations. Take some time to research and understand the different types of jigs and their features before making a decision.

Consider the Jig Type

The type of power doweling jig you choose will depend on the specific woodworking projects you intend to work on. There are two main types of jigs: self-centering doweling jigs and non-self-centering doweling jigs.

Self-centering doweling jigs are ideal for beginners or those who prefer a more simplified setup process. These jigs automatically center the drill bit, ensuring accurate and centered dowel holes. Non-self-centering doweling jigs require the user to manually align the holes, providing more control but also requiring more precision.

Consider your skill level and the complexity of your projects when deciding which type of jig to choose.

Check Compatibility with Your Project

Before purchasing a power doweling jig, it’s important to check its compatibility with your project. Ensure that the jig is suitable for the size and thickness of your workpiece. Some jigs may have limitations when it comes to accommodating larger or thicker materials, so make sure to consider your specific project requirements.

Additionally, consider the type of dowels you will be using. Some jigs may have specific hole sizes or configurations, so it’s important to choose a jig that will accommodate the dowels you plan to use.

Consider Jig Features

Different power doweling jigs come with various features that can enhance your woodworking experience. Some jigs may offer adjustable hole spacing to accommodate different dowel sizes or layouts. Others may have built-in clamps or guides to ensure stability and accuracy during drilling.

Consider the specific features that are important to you and your projects. For example, if you often work with different dowel sizes, a jig with adjustable hole spacing would be beneficial. Take the time to research and compare the features of different jigs to find the one that best suits your needs.

Preparing Your Workpiece

Once you have chosen the right power doweling jig for your project, it’s time to prepare your workpiece. Proper preparation ensures that your dowel joints will be strong, precise, and durable.

Measure and Mark the Locations for Dowels

Before you begin drilling, take accurate measurements and mark the locations where you want to place your dowels. Use a measuring tape, ruler, or any other measuring tool to measure and mark the spacing between dowels. Make sure to mark the same measurements on both pieces of wood that you intend to join.

Clamp Your Workpiece Securely

To prevent any movement or shifting during the drilling process, it’s crucial to securely clamp your workpiece. Use appropriate clamps to hold the workpiece firmly in place. Ensure that the clamps are tightened enough to provide stability but be careful not to damage the wood.

Create Pilot Holes

Creating pilot holes before drilling the dowel holes can help prevent the wood from splitting and provide guidance for accurate drilling. Use an appropriate size drill bit to create pilot holes at the marked locations. These pilot holes should be slightly smaller in diameter than the dowels you plan to use.

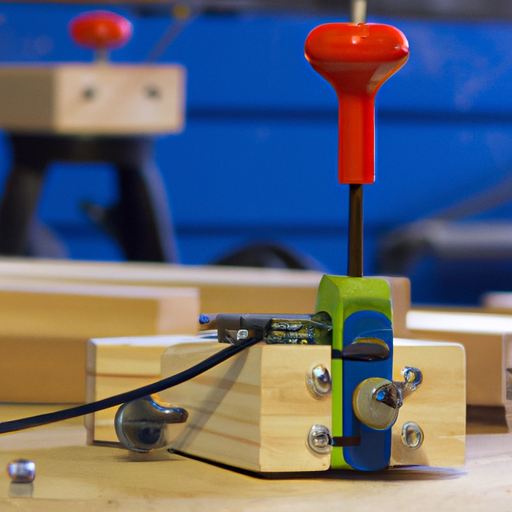

Setting Up the Power Doweling Jig

Once your workpiece is prepared, it’s time to set up the power doweling jig for drilling the dowel holes. Proper setup ensures precise and accurate holes that will result in strong and secure joints.

Insert Dowel Pins or Bushings

Depending on the type of power doweling jig you are using, you will need to insert dowel pins or bushings into the jig. Ensure that the pins or bushings are securely inserted and aligned according to the specified hole spacing.

Adjust Spacing and Alignment

Most power doweling jigs allow you to adjust the hole spacing to accommodate different dowel sizes and layouts. Take the time to adjust the spacing to match your project requirements. Additionally, double-check the alignment of the dowel pins or bushings to ensure that they are correctly aligned with the marked locations on your workpiece.

Secure the Jig to Your Workpiece

Before drilling, make sure that the power doweling jig is securely attached to your workpiece. Some jigs come with built-in clamps or guides that can be used to secure the jig in place. Ensure that the jig is stable and will not move during the drilling process.

Using the Power Doweling Jig

With the power doweling jig properly set up, you are ready to start drilling the dowel holes. Follow these steps to ensure accurate and precise drilling.

Align the Drill Guide with the Jig

Most power doweling jigs come with a drill guide that helps align and guide the drill bit. Align the drill guide with the dowel pins or bushings on the jig to ensure that the drill bit will be inserted into the correct location.

Set the Depth of the Drill Bit

To determine the appropriate depth for drilling, refer to the length of your dowels. Set the depth of the drill bit according to the desired depth of the dowel holes. Take care not to set the drill bit too deep, as it can weaken the joint.

Drill the Dowel Holes

With the drill bit properly set, slowly and carefully drill the dowel holes using the power doweling jig as a guide. Apply consistent pressure and maintain a steady hand to ensure clean and precise holes. Take your time and avoid rushing the drilling process to ensure optimal results.

Inserting the Dowels

After drilling the dowel holes, it’s time to insert the dowels. Properly inserting the dowels ensures a tight and secure joint that will withstand pressure and stress.

Apply Glue to the Dowel Holes

Before inserting the dowels, apply a small amount of woodworking glue to the inside of each dowel hole. This will help create a stronger bond between the dowel and the wood, ensuring a more secure joint.

Insert Dowels into the Holes

Once the dowel holes are glued, carefully insert the dowels into the holes. Ensure that the dowels fit snugly and align with the holes on the opposite piece of wood. Use a mallet or a hammer to gently tap the dowels into place.

Tap the Dowels Flush with the Surface

After inserting the dowels, use a chisel or a flush-cut saw to carefully trim the dowels flush with the surface of the wood. Take your time and ensure that the dowels are perfectly flush with the wood, as any unevenness can affect the final appearance of the joint.

Joining the Pieces

With the dowels inserted, it’s time to join the two pieces of wood together. Properly joining the pieces ensures a strong and secure joint that will withstand the test of time.

Apply Glue to the Mating Surfaces

Before joining the pieces, apply a thin layer of woodworking glue to the mating surfaces of the wood. This will create a stronger bond between the two pieces and ensure a more secure joint. Take care not to apply too much glue, as excessive glue can lead to messy joints.

Fit the Dowel Holes and Dowels Together

Carefully fit the dowel holes and dowels together, ensuring that the dowels align with the holes on the opposite piece of wood. Apply gentle pressure and ensure that the pieces are snugly connected. Take your time and make any necessary adjustments to ensure a perfect fit.

Clamp the Joint Tightly

To ensure a strong bond between the two pieces of wood, clamp the joint tightly using appropriate clamps. Ensure that the clamps are evenly distributed and apply enough pressure to hold the joint securely. Check for any gaps or misalignments and adjust the clamps as necessary.

Curing and Finishing

With the joint clamped tightly, allow the glue to cure according to the manufacturer’s instructions. Curing times may vary depending on the type and brand of glue used. Avoid moving the joint or applying any stress until the glue has fully cured.

Allow the Glue to Cure

During the curing process, it’s important to avoid any unnecessary movement or stress on the joint. Follow the manufacturer’s instructions to determine the recommended curing time. Curing times can vary, but it is generally recommended to leave the joint clamped for at least 24 hours.

Clean Up Excess Glue

After the glue has fully cured, remove any excess glue that may have squeezed out during the clamping process. Use a damp cloth or a scraper to carefully remove the dried glue. Take care not to damage the wood surface or affect the appearance of the joint.

Sand and Finish the Joint

Once the excess glue has been removed, sand the joint to smooth out any imperfections or rough edges. Start with a coarse grit sandpaper and gradually move to finer grits for a smooth and polished finish. Apply a suitable finish or stain to enhance the appearance of the joint and protect the wood.

Tips and Tricks

When using a power doweling jig for creating dowel joints, keep the following tips and tricks in mind to ensure successful and professional-looking results.

Practice on Scrap Wood First

If you are new to using a power doweling jig, it’s a good idea to practice on scrap wood before working on your actual project. This will give you a chance to familiarize yourself with the tool and technique and make any necessary adjustments before working on your final piece.

Use the Appropriate Drill Bit Size

Using the correct drill bit size is crucial for creating accurate and precise dowel holes. Refer to the size of your dowels and choose a drill bit that matches the diameter of your dowels. Using the wrong drill bit size can result in loose or poorly fitting dowels.

Double-Check Alignment Before Drilling

Before drilling the dowel holes, double-check the alignment of the jig, dowel pins or bushings, and the marked locations on your workpiece. Any misalignment can result in uneven or inaccurate holes, affecting the overall integrity of the joint. Take the time to ensure everything is properly aligned before proceeding with drilling.

Common Mistakes to Avoid

To ensure successful dowel joints, avoid these common mistakes that can compromise the strength and quality of your joints.

Misaligned Dowel Holes

Improper alignment of the dowel holes can result in joints that are weak and unstable. Take the time to accurately mark and align the dowel hole locations, and double-check the alignment before drilling. Proper alignment is crucial for creating strong and secure joints.

Insufficient Clamping Pressure

Insufficient clamping pressure during the gluing and joining process can result in weak joints that are prone to separation. Ensure that you apply enough pressure when clamping the joint to achieve a strong and secure bond. Check for any gaps or misalignments and adjust the clamps as necessary.

Using the Wrong Drill Bit

Using the wrong drill bit size can result in dowel holes that are either too loose or too tight. Refer to the size of your dowels and choose a drill bit that matches the diameter of your dowels. Using the correct drill bit size is crucial for creating accurate and well-fitting dowel holes.

Conclusion

Using a power doweling jig for creating dowel joints can greatly enhance the strength and durability of your woodworking projects. By choosing the right jig, properly preparing your workpiece, setting up the jig correctly, and following proper techniques, you can achieve professional-looking joints that will stand the test of time. Remember to take your time, practice on scrap wood, and avoid common mistakes to ensure successful and satisfying results. With the right skills and tools, you can master the art of creating strong and secure dowel joints. Happy woodworking!